Concrete testing services

Hanson Concrete operates regional technical teams across the North, Central and South of the UK. Our experienced, mobile quality control technicians visit sites to obtain test samples for our rigorous internal quality control system and are always on hand to offer professional advice. All Hanson samples are tested at our national UKAS accredited laboratory in accordance with current European and British Standards under third party accreditation by the Quality Scheme for Ready-mixed Concrete.

Test results are then supplied to our national data centre where our advanced control systems are maintained autonomously from regional interference. Hanson are the only national company to operate in this manner which provides the highest possible level of data integrity.

Research into the latest technologies and product development is shared between the national laboratory and within the regions. Where necessary, Hanson can draw on the vast expertise and resources available at our parent company, Heidelberg cement’s technical centre, one of the largest facilities of its kind anywhere in the world.

Concrete testing services

Hanson Concrete’s national laboratory is fully equipped to provide a range of testing services in accordance with British and European Standards.

We offer on-site sampling and testing to help demonstrate compliance with your concrete specification requirements, as well as a collection and testing service for site manufactured samples.

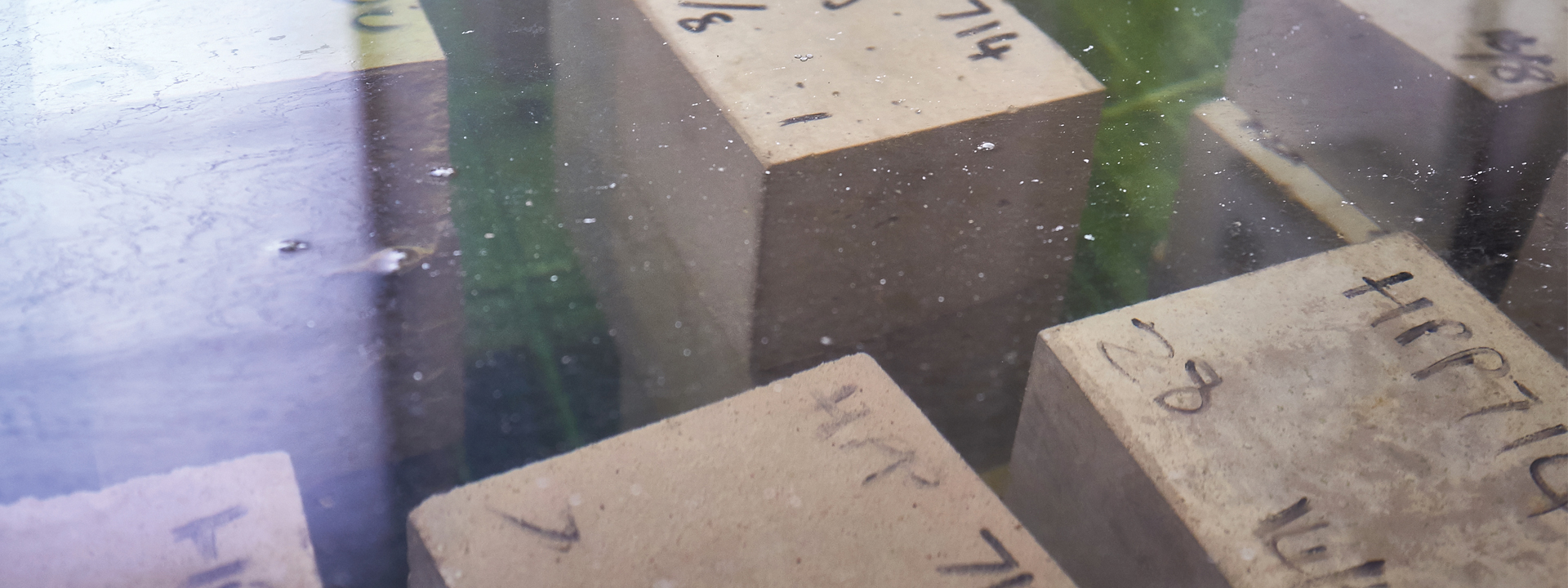

Concrete cube compression testing

The vast majority of testing is designed to prove that the hardened concrete will develop the required level of compressive strength within the required time frame. As well as measuring strength, our service would typically include the measurement of consistence and, where specified, the air content of the concrete supplied.

All concrete cubes are stored in our purpose-built temperature-controlled curing tanks in readiness for testing at our national laboratory. The temperature is maintained at 20°C in full accordance with the requirements of EN206-1 and BS8500

Before they are tested, each sample is inspected visually to identify any damage; weighed to measure the density; and measured to ensure the dimensions are within permissible tolerances. Variations in any/all of these criteria may affect the test results.

The hardened concrete cubes are tested for compressive strength at 7, 28 and 56 days after casting by crushing, in accordance with BS EN 12390-3. Where required results can be emailed immediately, and test certificates are normally issued within 48 hours of completion.

Technical advice and support

We have a technical team on hand to offer additional advice and assistance with appropriate concrete mix selection. We are also able to provide CPD approved presentations to improve knowledge and competitiveness; these can be delivered both at our head office and regionally on specific subjects. Alternatively, our team will speak in-house on key topics tailored to your company’s learning requirements.